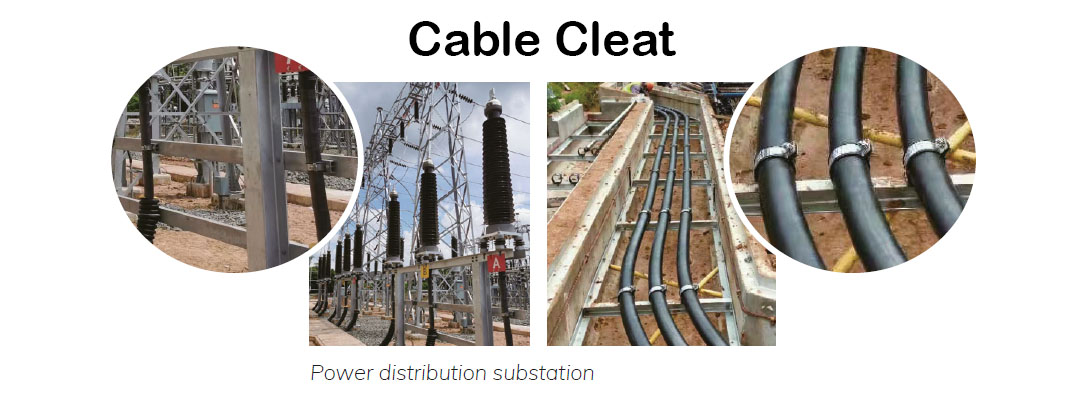

A cable cleat is a device designed to secure and support cables in electrical installations, particularly in situations where short circuits, mechanical stress, or vibrations might occur. Cable cleats ensure that cables remain fixed in place, preventing damage and maintaining the integrity of the electrical system.

Key Features of Cable Cleats:

-

Material: Cable cleats are often made from materials like stainless steel, aluminum, or polymeric/nylon materials to provide durability and resistance to corrosion.

-

Applications: Commonly used in industrial settings, renewable energy projects, power distribution systems, and areas where high-voltage cables are installed.

-

Compliance: Must adhere to international standards such as IEC 61914, which defines the performance and testing requirements for cable cleats.

Types of Cable Cleats:

-

Single Cable Cleats: Designed to secure single cables.

-

Trefoil Cleats: Used for three-phase systems where cables are arranged in a trefoil (triangle) formation.

-

Multicore Cleats: Designed to hold multiple cables simultaneously.

-

Heavy-Duty Cleats: For installations requiring support under high mechanical stress or short circuit conditions.

Advantages:

-

Prevents cable movement during short circuits.

-

Enhances safety by reducing the risk of electrical hazards.

-

Ensures cable longevity by minimizing mechanical strain.

-

Simplifies cable management.

Installation:

-

Typically mounted on structures like walls, cable trays, or ladder systems.

-

Spacing between cleats depends on the cable size, weight, and expected mechanical stress.

Would you like information on specific applications of cable cleats, installation procedures, or selection guidelines?